- BI-ALFA

- HM-TITAN

- RRR

- GRIT

- HACKSAW BLADES

bi-alfa Master

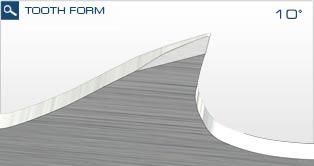

The RÖNTGEN bi-alfa Master band saw blade harnesses the benefits of “triple chip” tooth geometry, widely recognised as the optimal form for production sawing. The teeth are CBN precision ground to form a chamfered high tooth (A) and a pair of lower finishing teeth (B & C). Cutting faces are ground parallel to the back edge ensuring absolutely straight cutting. The M42 tooth tips have a height difference calculated to suit the typical chip load characteristics of each blade width/pitch combination. High cutting rates can be achieved without compromising blade life or cut finish.